In the competitive landscape of plastics manufacturing, quality is of utmost importance. The greater efficiency reduced costs and overcame overall expenses. The Parison blow molding electronic pressure regulator creates hollow plastic objects.

It helps to produce quality plastic products. It depends on precise control of air to inflate the molten plastic parison. The electronic pressure regulator (EPR) makes the Parison blow molding simple and precise. The process becomes not just an upgrade but an indispensable tool.

The top advantage of the Parison blow molding electronic pressure regulators is presented here:

1. Precision in Wall Thickness Control

The significant challenge in blow molding is to achieve uniform wall thickness. The material viscosity can lead to inconsistent thickness of the plastic products. The reason for this may be due to weak points or excessive material use.

The electronic proportional pressure regulator provides micro-level control on the inflation process. This adjusts the pressure throughout the blow cycle for the creation of better quality products.

2-Optimal Material Distribution:

This avoids the plastic from conforming to the mold cavity. This ensures the optimal material distribution around the molding dyes. This is possible only by superior control over the production process.

This allows for final products to be in good shape and simple to provide quality products. The optimal control over the production process enables the management of quality. Material distribution is not as simple as the inflation process.

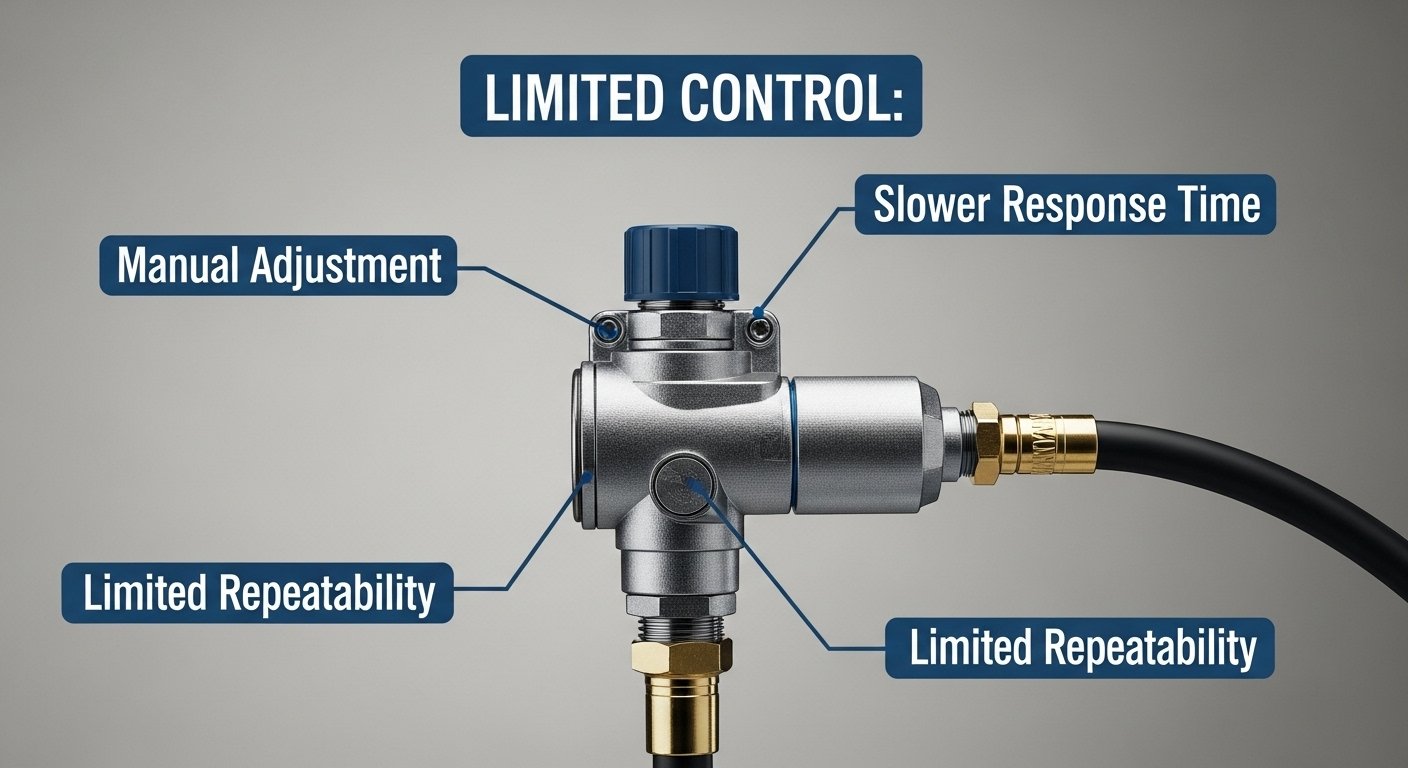

3. Repeatability and Consistency:

In a high-volume production process, the Parison blow molding electronic pressure regulator helps in the repeatability of the process. The main reason consistency is king in the production process.

Every bottle, container, or object prepared from plastic must meet the exact specifications of the production process. Mechanical regulators inherently suffer from hysteresis and drift due to their inconsistent pressure management. This makes it difficult to achieve identical results for a longer time.

4-Closed-Loop Feedback Systems:

The electro pneumatic regulators with their closed-loop feedback systems provide consistency in the production process. The digital control ensures that once an optimal pressure profile is established, it is maintained for repeated production processes.

It is replicated with extreme accuracy across every single part production process of Palstice. This reduces product variability over time and enhances overall product reliability during the production term of production.

5-Dynamic Pressure Profiling Capabilities:

The static mechanical regulators are not able to provide the dynamic pressure capabilities. The inflation process is the key to the production of plastic objects. The customizable sequence and process management are required to get control over the blow cycle.

A brand can achieve unparalleled precision, consistency, and efficiency in its processes. The electronic proportional pressure regulator directly contributes to higher-quality products and a more competitive market position.

Take Away:

Parison blow molding electronic pressure regulator is not merely an optional upgrade. The fundamental requirement for any blow molding operation. It is aiming for peak performance of operational performance. A brand can achieve unparalleled precision, consistency, and efficiency in its processes. The electronic proportional pressure regulator directly contributes to higher-quality products and a more competitive market position.